Innovative error prevention: laser marking system optimizes cleanroom production

15.07.2024

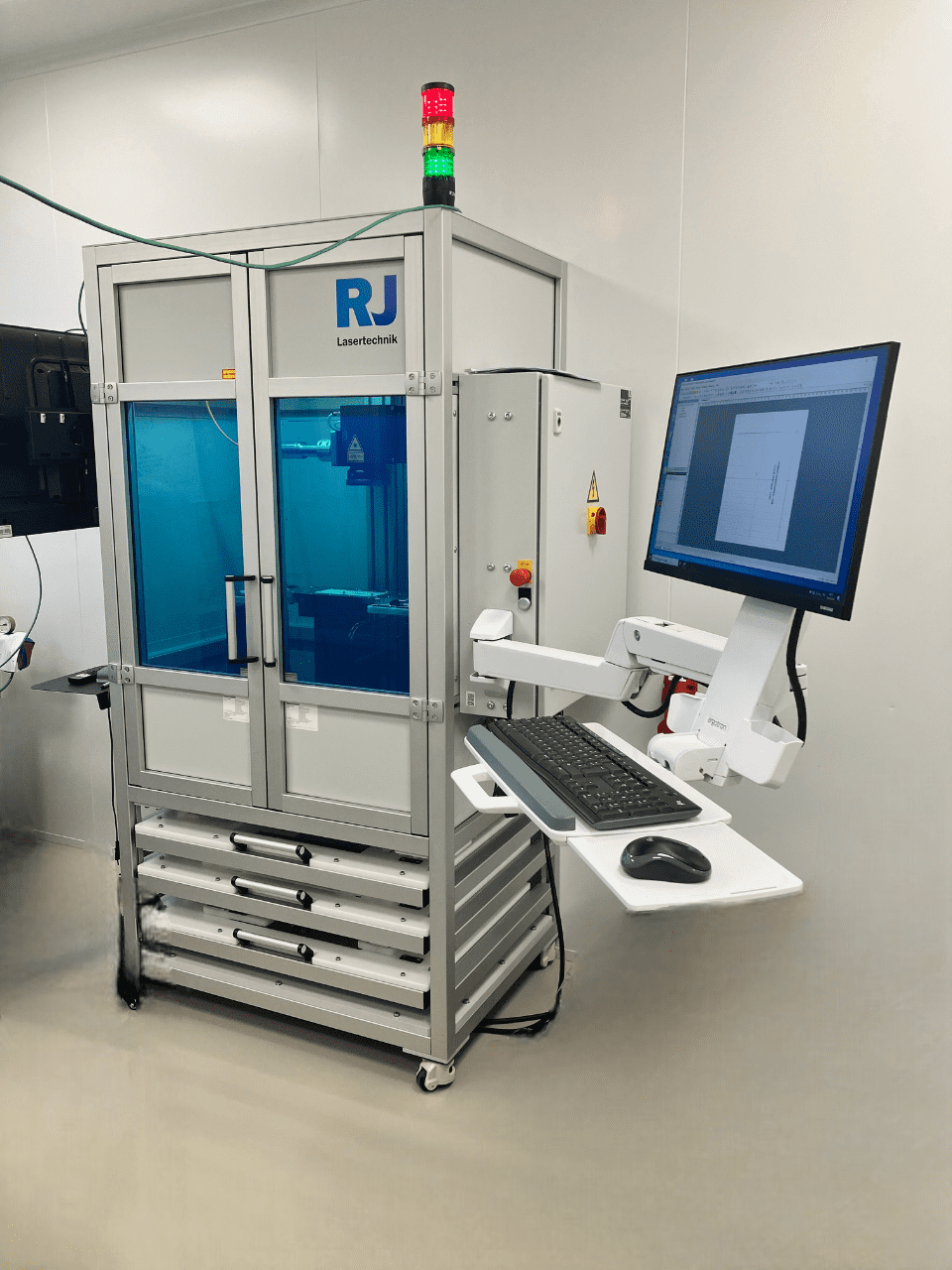

The new system marks customer components with serial and production numbers

Cleanroom production at RJ Lasertechnik has been further expanded and equipped with an innovative laser marking system, which was also developed according to Poka Yoke principles. The new marking system enables the precise marking of customer components with serial and production numbers as well as DMC codes, which significantly improves traceability and quality assurance.

The system works with interchangeable fixtures that are aligned in a standard fixture to ensure that the components are positioned correctly and cannot be twisted. Operators can simply insert the components and trigger the marking, with the serial number also serving as a quality seal.

The commissioning of the innovative laser marking system is a further step on the way to error-free production and underlines our commitment to implementing the highest quality standards in production. Customers from sectors such as medical and semiconductor technology, in particular, who have to guarantee the highest standards, benefit from our pioneering technology.